Darren has mentioned the CNC DIY phono stage in

http://www.psaudio.com/article/cnc-moving-magnet-cartridge-phono-stage-part-2/ and http://www.psaudio.com/article/39395/

Once the printed wiring boards (PWBs) are available you can go to the DigiKey cart that Darren has set up to buy parts here: http://www.digikey.com/short/35wh82

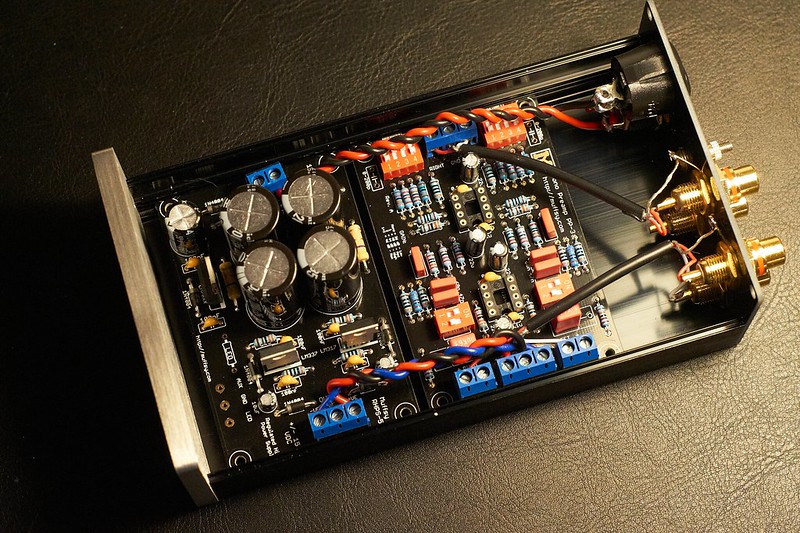

There’s an entire thread at AudioKarma.org, replete with over 133 pages, that discuss the CNC phono stage. But here’s a link to the page showing the boards that Darren is arranging to get for us: http://audiokarma.org/forums/index.php?threads/another-super-high-end-phono-stage-no-expense-spared.371889/page-119

I’ve arranged to buy my resistors from partsconnexion.com, as they have the PRP resistors that Paul uses in the PWD and DS, (well, and just about everything else) The OPA 2134 op-amps are about a buck cheaper per unit at partsconnexion than DigiKey. Well, once they come from their vendor, that is, as they’re back-ordered.

Here are the part numbers for the PRPs:

I will most likely use a pair of the AA battery holders ( https://www.jameco.com/webapp/wcs/stores/servlet/ProductDisplay?storeId=10001&langId=-1&catalogId=10001&productId=2207021 ) and plug them into jacks on the housing for easy access to change batteries. https://www.jameco.com/webapp/wcs/stores/servlet/ProductDisplay?storeId=10001&langId=-1&catalogId=10001&productId=151555 (I always hated the 9V snap clip as it can lead to reverse power if one is not careful. Besides, the AA will last longer. I hope.)

So, while I’m waiting for parts and boards I dug out my old turntable I bought 30 years ago and discovered the Grace F8 cartridge I bought is no longer made. After some searching, there is a replacement needle I can buy for it that will fit (was meant for a Shure, but it apparently works for the F8)

So, looking at the turntable (with its built-in interconnects) and a cartridge that no one knows anything about, what values do I use for the load resistors and capacitors on the front end?

(see next post, as this one is getting rather long)