Curious… why the output transformer at all? Is there DC on the primary side? Is the transformer being used to isolate other elements? Why not a high quality capacitor?

As I understand it, the transformers act „just“ as a low pass filter - to filter out all the unwanted high frequency noise from the DSD signal to only let pass the relevant (audio) frequencies. This is where the digital signal gets truncated to act as an analog output line level voltage signal. Genius.

Having a background of 30 years in the electronics repair industry, here are my instructions for replacing the output transformers. Use a low wattage soldering pencil, not a gun!

In my years I have soldered on double sided circuit boards, removed and installed surface mounted components, 64 pin chips, etc.

- Use an anti-static mat and grounded arm band at all times during the entire process. You can get these on Amazon.

- Remove the existing transformers by clipping the legs.

- Use solder wick or better yet, a solder sucker to remove the solder around the remaining pins.

- Using small needle nose pliers, grasp the pin and while heating the pad below, remove the pins. Clean the pads if needed.

- Insert the new transformers.

- Use 4% silver solder and solder in. The result should be a smooth shiny solder surface, no jagged edges.

- Good soldering practice would be to make sure the soldering iron tip is properly tinned. Touch the tip to the solder pad, then feed in solder by touching the pad and soldering iron tip at the same time with the solder. The goal is to spend the least amount of time as possible when applying heat to the pads for the whole removal and installation process.

What would be your recommended solder pencil temperature with the 4% silver solder?

40 watt pencil iron is ideal. Be sure it is properly tinned. The Weller pencil irons are the best, especially if you have the variable temperature version, although can be expensive. But hey, you will then have one for other projects!

Having a Hakko Solder Station that allows for fairly accurate temperature settings. My thought would be to set it at 675F. I’d consider a range of 650F to 750F for 4% silver solder.

Wonderful, helpful, practical information. Thank you!

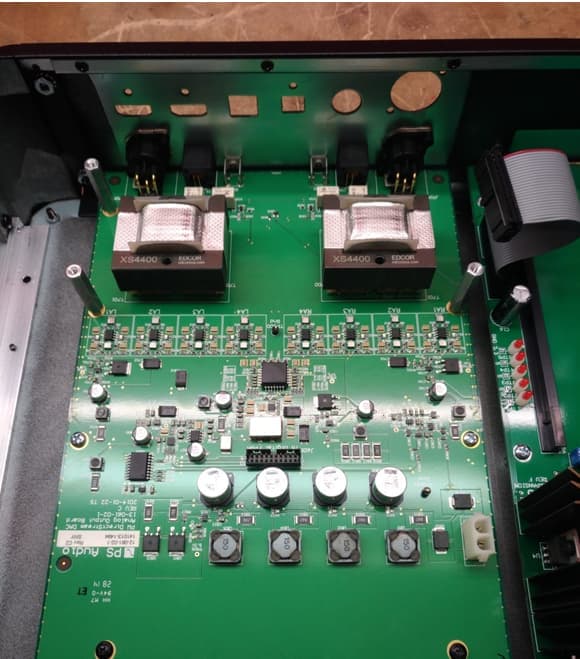

Just got back my DSD Sr. DAC with the Edcor XS-4400 mod upgrade from Audiophonie in Montreal (Quebec, Canada) and Arnaud the technician did a wonderful job (1hr job at the cost $90.00 Canadian dollars).

I just hooked up my DAC, and the first impression is extremely positive: beautiful highs and much richer medium with better separation (the echo in the Church is more present - easier to discern), better communication of the emotions.

And I will keep listening for improvement during this coming week as the breaking-in continues …

I have already listened to the Hugo TT2, Bricasti M3, Jadis JS2 and Meitner MA3 DACs, and while they were similar priced or more expensive, I did not find them better than my DSD Sr. DAC with the original transformers (i.e. before the upgrade).

Therefore, if things just keep getting better, I probably will not be changing my DAC any time soon

Very nice!

Let us know what your experience is in a week or two.

Will do  …

…

Thanks for the info!

Your very welcome!

Clipping the legs sounds simple, but if the existing transformers are mounted close to the board, you’ll need a very thin but stout ‘clipping’ device that can be maneuvered in a very tight space without hitting anything else on the board. Do you have a recommendation for an appropriate tool?

I don’t believe there’s such a tool. Any clipper strong enough to do the job will not fit in the space without damaging the board. If there is a way or a tool to clip off the transformers, I would also like to learn about this tool.

Are you sure this tool can fit between the transformer and board? Have you actually tried cutting the transformer pins with this tool. I use a Hakko CHP 170 Micro Cutter and no way it would fit between to cut the pins. It’s the same size as your IGAN 170 wire cutters.

My choice, I have quite a few Knipex cutters. They are all excellent.

Guys, I realise you want to do a good job of this and reduce any risk of cooking the board. But it’s really not necessary to clip the wires on the original transformer. They’re nice and thin so they don’t suck up the heat much.

Just use a decent vacuum desoldering station like this from aliexpress. There are lots of models on ebay. I borrowed one of these from a friend who has everything

Full disclosure I am not trained in soldering though have done a lot with just an iron and manual solder sucker. I’m giving you my experience so all this careful talk doesn’t put you off trying it. However if you meet a problem during the process just stop and ask for help on the forum.

I use 4% silver solder and practised on an old pcb before leaping into the real job. I really recommend a bit of practise.

The main thing is to do the job quickly. I used a fine point tip rather than a big spade. It’s much better to set the temperature higher (30ºC or so) than usual so the solder melts quickly. This gets the job done faster and cleaner and you don’t heat the board up as much. Tin the tip with some solder before making contact as the molten solder transfers heat to the old solder much faster than a dry tip.

I had only one sticky pin that needed some help as it stayed in firm contact with the copper track. I just flicked it away from the board it with a screwdriver while desoldering.

I was very happy how quick and easy this was to do and well. Please don’t try this if you don’t have experience and confidence with soldering.

Excellent!

This is for Ted. Should one wear a static wrist strap as well as use a static mat when doing the transformer mod? My concern is the digital board that must be removed to access the audio board.