Steven, I know you just pointed this site out, this has nothing to do with finding fault with you, it is finding fault with what is provided to you, the customer. The level of data is what most of you have to go on buying a cable. This is wrong.

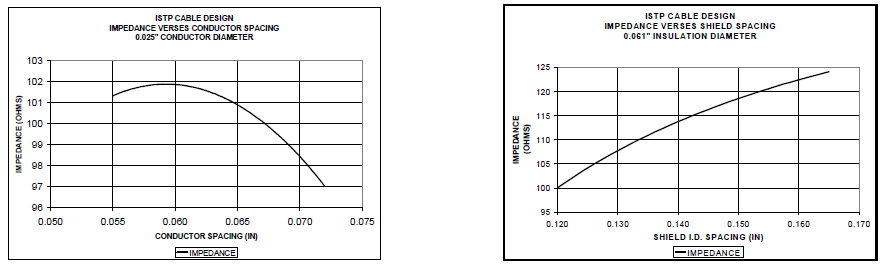

I’ll leave it to readers to review what the site provides and if it has any truly verifiable information. It is up to the manufacturer’s to be transparent when demonstrating HOW a cables works with test data.The version with aluminum sheath COMPLETELY changes the cable! And yes, this is what SHIELDS do, change the cable’s parameters significantly.

Vp at the low end is controlled by;

Vp= SQRT[2 X OMEGA/ (RC)], where OMEGA is 2 x pie x f.

or…

Zo=101670 / C X Vp can be used, and solve for Vp, if you know the impedance at each frequency.

Adding a shield changes C, and thus at every frequency Vp changes, too. Worse, C is not influenced uniformly down the cable since the shield geometry relative to the core wires is hard to make 100% consistent along a less than uniform structure. I already showed this with actual charts above. Shields are used ONLY under extreme circumstances of S/N ratios. Most Heavy Industries use UTP Ethernet as an example for it’s superior Shannon’s law bandwidth. Shields knock about 6 dB of NEXT out of the cable all things the same, and the NEXT loss better be less than the S/N that a shield works against or it is not a fair trade. Shielded cables have to be far more perfect to collect back what is lost using a shield.

As time goes on, more and more of you will begin to see that a WHOLE LOT of this is not undefined. Yes, we have a few areas, material structure, current coherence as examples. This does not allow a free-for-all in designing cables! Every single KNOWN parameter can be calculated, measured, and compared to best practice, always.

The advertisements for most cables could be IDENTICAL and just substitute a different picture (I have a hard time saying it is a DESIGN with virtually zero evidence of how it works). All the same magic words and phrases apply.

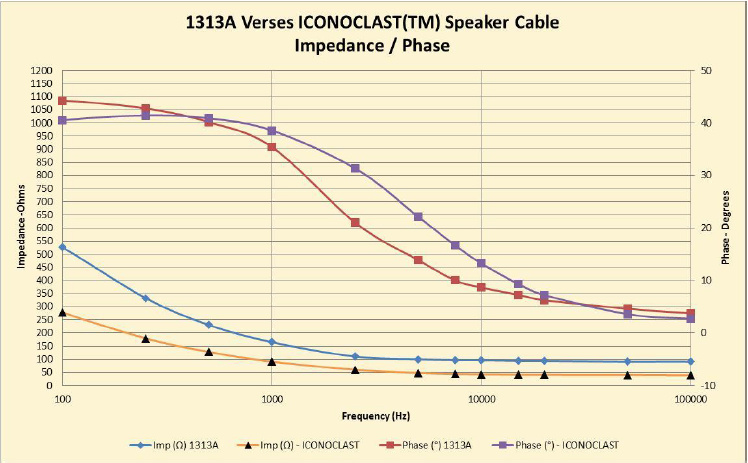

Sorry, I don’t get it. I didn’t get it 4 years ago and less so today. This is why ICONOCLAST provides heaps of data on EVERY design to show exactly how R, L and C are reached. The unknowns REMAIN unknown and I’ll tell you that. I won’t replace unknowns with, “this seems wrong but it works”. I’d rather see, “the numbers are right, but can you that that?”

Some sites can’t even tell you why one big wire works OK for treble! As frequency goes up, you want MORE surface area and big wire provides that. How hard is this to say? Several smaller wires of the same total CMA area can have MORE surface area, but present a tremendous design challenge to manage R, L and C. The complexity is worth it if you can actually DESIGN a cable. This is what design is all about with cars, washing machines, airplanes you name it. A BALANCE of multivariant variables.

Until known calculations and measurements are used evaluate HOW to best balance audio, we will never get to a truly optimized design. I refuse to put a full page ad in front of you, ask you for your money, and provide not a single spec other than something like, “it is wrong but it works”. THAT is a specification? Can you make an amplifier WRONG on purpose and somehow sell it? I just told you something is WRONG and if it is a cable this is good? Why the hell have I been working so hard?

If it WORKS it can be fully supported as to WHY it is working with the calculations and measurements used to define the DESIGN. Exactly WHY is this design a good balance of R, L and C and tertiary parameters?

I’d rather be a total fool in making an error after peer review and making corrections towards total transparency than to market what passes for data and design proofs elsewhere. I can take ANY design and calculate and measure HOW it fundamentally works, so can they. They won’t, because it will show how the design fails to fully balance what you’re paying for. Most have no clue what the cable even does to accepted standards.

My peer review papers are there to PROOF and find errors in calculation or measurement to further move to FACTUAL variables that can be reproduced. Every cable is looked at this way. Every DEFICIENCY is pointed out as ALL passive cables have them. This is NOT the “problem” per say but the trade-offs needed to mitigate the problems is the problem. What’s the best COMPROMISE and how was it reached?

Maybe when vendors that do have well DESIGNED cables (they should know how they work) show with full disclosure the trade-offs to mitigate cable non linearity we will begin to get somewhere. Cable data can be used to isolate particular sonic merits much like loudspeakers. As it is now, with virtually NOTHING but well wishing words, well…nothing will improve.

Cable, like speakers, can FULLY disclose HOW the designs work and where they don’t. Like a speaker, there is nothing wrong with this approach. Compare each cable to a full set of agreed upon measurements and we can decide what optimizations work for us. Cables that are way off the mark on reaching best in class metrics across several standards can’t possibly sound better. We all know horns, ports, air suspension, dynamic electrostatic are all different and measurably so. We pick what deficiencies effect use the least. You can’t do this with a cable…yet.

Someone has to honestly provide real data to start this line of thinking. There are measures that show merit AND additional deficiencies that I don’t have yet. This is where peer review and a standardized set of ongoing tests provide; improvements in understanding what EVERY cable is doing.

Galen